Standardized High-Current Connectors

Economical & Delivered Fast

While Globetech is known for making the world's best custom connectors, we also offer a range of standardized ones. These meet the same high levels of reliability and durability that our customers expect.

Since we keep them in stock at all times, if they meet your needs, you may prefer them since they ship faster and at a lower cost than our custom solutions.

Globetech's high current connector, "Thread Contact Series" provides stable and highly reliable performance in all applications such as automotive inspection and semiconductor manufacturing equipment.

However, if none of our standardized products fit your needs, please talk to us about custom solutions.

Features

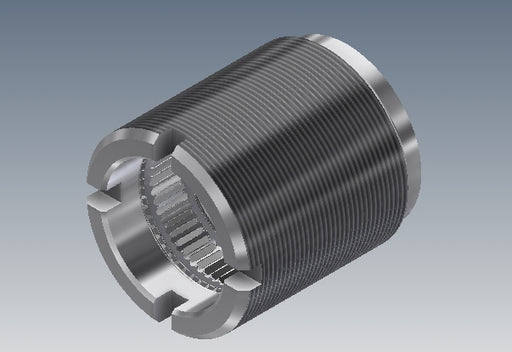

- Stable energization is achieved by using a contact band.

- Choose the model which suits your requirements.

- Quick delivery.

- Economical.

- Customization, such as changing the material, is also possible upon request.

Lineup

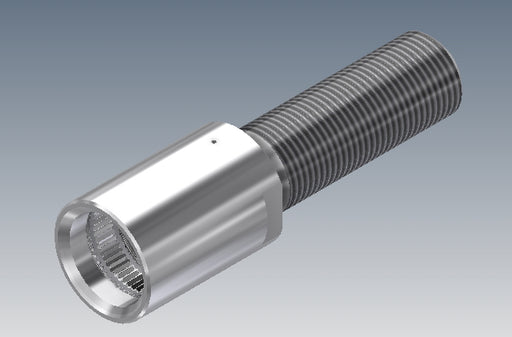

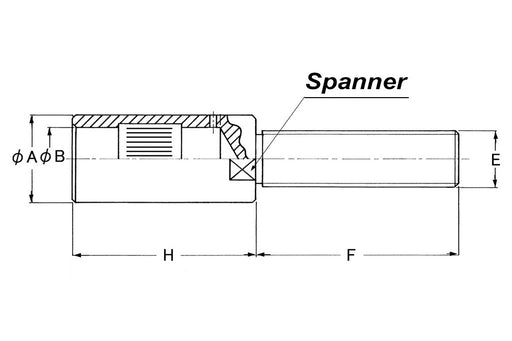

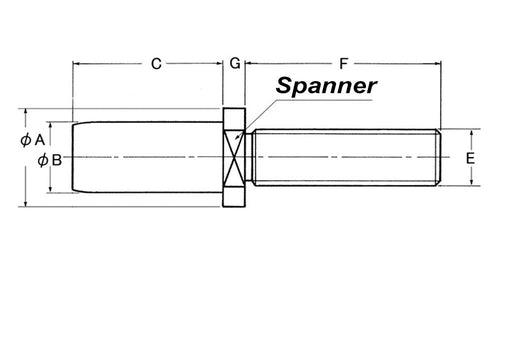

Sockets with Thread Termination

- Conductor: Brass/silver plating

- Contact:

- Beryllium copper alloy/gold plating for φ2 to φ6

- Beryllium copper alloy/silver plating for φ8 and above

- Heat Tolerance: Up to 145 ℃ (293 °F)

| Model | φB inches / mm |

Rated Current (A) |

φA inches / mm |

E mm |

F inches / mm |

H inches / mm |

For Spanner inches / mm |

Withdrawal Force (Kg / N) |

Insertion Force (Kg / N) |

Contact Resistance (μΩ) |

Weight (g/OZ) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MS2 | .08/2 | 25 | .22/5.5 | M3 | .63/16 | .79/20 | .16/4 | 0.6/5.9 | 0.8/7.9 | 300 | 4/0.14 |

| MS3 | .12/3 | 35 | .24/6 | M4 | .79/20 | .79/20 | .20/5 | 0.8/7.9 | 1/9.8 | 200 | 5/0.18 |

| MS4 | .16/4 | 50 | .28/7 | M5 | .98/25 | .98/25 | .24/6 | 1.5/14.7 | 2.2/21.6 | 180 | 9/0.32 |

| MS5 | .20/5 | 70 | .33/8.5 | M5 | .98/25 | .98/25 | .28/7 | 1.6/15.7 | 2.2/21.6 | 150 | 11/0.39 |

| MS6 | .24/6 | 90 | .39/10 | M6 | 1.10/28 | .98/25 | .31/8 | 2/19.6 | 2.5/24.5 | 100 | 15/0.53 |

| MS8 | .31/8 | 125 | .55/14 | M8 | 1.42/36 | 1.65/42 | .43/11 | 2/19.6 | 2.5/24.5 | 60 | 47/1.66 |

| MS10 | .39/10 | 180 | .63/16 | M10 | 1.65/42 | 1.65/42 | .51/13 | 3/29.4 | 3.5/34.3 | 50 | 67/2.36 |

| MS12 | .47/12 | 230 | .71/18 | M12 | 1.89/48 | 1.65/42 | .51/13 | 3/29.4 | 3.6/35.3 | 40 | 88/3.1 |

| MS14 | .55/14 | 280 | .79/20 | M14 | 1.97/50 | 1.89/48 | .67/17 | 4.6/45.1 | 5.1/50 | 35 | 123/4.34 |

| MS16 | .63/16 | 340 | .87/22 | M16 | 2.28/58 | 1.89/48 | .75/19 | 6.6/64.7 | 7.1/69.6 | 25 | 163/5.75 |

| MS18 | .71/18 | 400 | .98/25 | M16 | 2.28/58 | 2.05/52 | .87/22 | 7.6/74.5 | 10.2/100 | 20 | 196/6.91 |

| MS20 | .79/20 | 460 | 1.10/28 | M18 | 2.76/70 | 2.05/52 | .94/24 | 8.1/79.4 | 12.2/119.6 | 15 | 270/9.52 |

| MS25 | .98/25 | 620 | 1.50/38 | M20 | 2.91/74 | 2.95/75 | 1.26/32 | 8.1/79.4 | 12.2/119.6 | 10 | 600/21.16 |

| MS30 | 1.18/30 | 800 | 1.65/42 | M24x2 | 3.23/82 | 2.95/75 | 1.42/36 | 10.2/100 | 12.2/119.6 | 9 | 740/26.10 |

| MS35 | 1.38/35 | 1000 | 1.89/48 | M30x2 | 3.54/90 | 2.95/75 | 1.61/41 | 12.2/119.6 | 15.3/150 | 8 | 1080/38.10 |

| MS40 | 1.57/40 | 1200 | 2.05/52 | M36x3 | 4.13/105 | 2.95/75 | 1.81/46 | 12.2/119.6 | 15.3/150 | 7 | 1430/50.44 |

| Model | φB inches / mm |

Rated Current (A) |

φA inches / mm |

|

C inches / mm |

E mm |

F inches / mm |

G inches / mm |

Weight (g/OZ) |

|---|---|---|---|---|---|---|---|---|---|

| MP2N | .08/2 | 25 | .19/4.7 | .16/4 (hex) | .65/16.5 | M3 | .63/16 | .12/3 | 2/0.07 |

| MP3N | .12/3 | 35 | .23/5.8 | .20/5 (hex) | .65/16.5 | M4 | .79/20 | .14/3.5 | 3/0.11 |

| MP4N | .16/4 | 50 | .28/7 | .24/6 (hex) | .77/19.5 | M5 | .98/25 | .16/4 | 6/0.21 |

| MP5N | .20/5 | 70 | .32/8.1 | .28/7 (hex) | .77/19.5 | M5 | .98/25 | .16/4 | 8/0.28 |

| MP6N | .24/6 | 90 | .37/9.3 | .31/8 (hex) | .77/19.5 | M6 | 1.10/28 | .16/4 | 12/0.42 |

| MP8N | .31/8 | 125 | .50/12.7 | .43/11 (hex) | 1.34/34 | M8 | 1.42/36 | .20/5 | 31/1.09 |

| MP10N | .39/10 | 180 | .59/15 | .51/13 (hex) | 1.34/34 | M10 | 1.65/42 | .20/5 | 51/1.80 |

| MP12N | .47/12 | 230 | .71/18 | .51/13 (D-cut) | 1.34/34 | M12 | 1.89/48 | .20/5 | 79/2.79 |

| MP14N | .55/14 | 280 | .79/20 | .67/17 (D-cut) | 1.50/38 | M14 | 1.97/50 | .28/7 | 121/4.27 |

| MP16N | .63/16 | 340 | .87/22 | .75/19 (D-cut) | 1.50/38 | M16 | 2.28/58 | .28/7 | 170/6.00 |

| MP18N | .71/18 | 400 | .98/25 | .87/22 (D-cut) | 1.65/42 | M16 | 2.28/58 | .28/7 | 203/7.16 |

| MP20N | .79/20 | 460 | 1.10/28 | .94/24 (D-cut) | 1.65/42 | M18 | 2.76/70 | .28/7 | 271/9.56 |

| MP25N | .98/25 | 620 | 1.50/38 | 1.26/32 (D-cut) | 2.44/62 | M20 | 2.91/74 | .35/9 | 506/17.85 |

| MP30N | 1.18/30 | 800 | 1.65/42 | 1.42/36 (D-cut) | 2.44/62 | M24x2 | 3.23/82 | .35/9 | 745/26.28 |

| MP35N | 1.38/35 | 1000 | 1.89/48 | 1.61/41 (D-cut) | 2.44/62 | M30x2 | 3.54/90 | .39/10 | 1149/40.53 |

| MP40N | 1.57/40 | 1200 | 2.05/52 | 1.81/46 (D-cut) | 2.44/62 | M36x3 | 4.13/105 | .43/11 | 1656/58.41 |

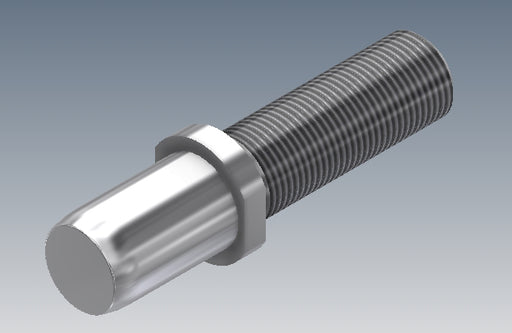

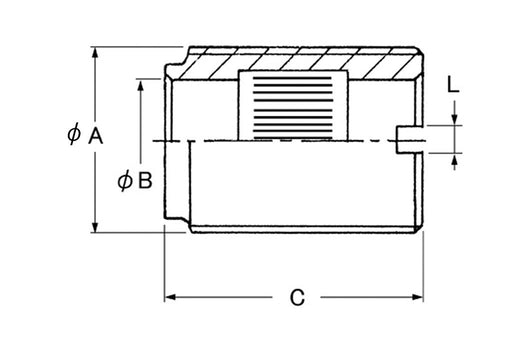

Sockets with External Thread Termination

- Conductor: Brass/silver plating

- Contact:

- Beryllium copper alloy/gold plating for φ2 to φ6

- Beryllium copper alloy/silver plating for φ8 and above

- Heat Tolerance: Up to 145 ℃ (293 °F)

| Model | φB inches / mm |

Rated Current (A) |

φA mm |

L inches / mm |

L inches / mm |

Withdrawal Force (Kg / N) |

Insertion Force (Kg / N) |

Screw fastening force(max) (Kg.m / N.m) |

Contact Resistance (μΩ) |

Weight (g/OZ) |

|---|---|---|---|---|---|---|---|---|---|---|

| MS2N | .08/2 | 25 | M8x0.75 | .65/16.5 | .06/1.5 | 0.6/5.9 | 0.8/7.9 | 0.3/2.94 | 300 | 5.1/0.18 |

| MS3N | .12/3 | 35 | M8x0.75 | .65/16.5 | .06/1.5 | 0.8/7.9 | 1/9.8 | 0.3/2.94 | 200 | 5.2/0.18 |

| MS4N | .16/4 | 50 | M8x0.75 | .77/19.5 | .06/1.5 | 1.5/14.7 | 2.2/21.6 | 0.3/2.94 | 180 | 6/0.21 |

| MS5N | .20/5 | 70 | M10x1 | .77/19.5 | .06/1.5 | 1.6/15.7 | 2.2/21.6 | 0.5/4.9 | 150 | 7.2/0.25 |

| MS6N | .24/6 | 90 | M12x1 | .77/19.5 | .08/2 | 2/19.6 | 2.5/24.5 | 1/9.81 | 100 | 11/0.39 |

| MS8N | .31/8 | 125 | M14x1 | 1.34/34 | .10/2.5 | 2/19.6 | 2.5/24.5 | 1.3/12.75 | 60 | 22/0.78 |

| MS10N | .39/10 | 180 | M18x1 | 1.34/34 | .14/3.5 | 3/29.4 | 3.5/34.3 | 2.3/22.56 | 50 | 40/1.41 |

| MS12N | .47/12 | 230 | M20x1 | 1.34/34 | .14/3.5 | 3/29.4 | 3.6/35.3 | 3.1/30.4 | 40 | 44/1.55 |

| MS14N | .55/14 | 280 | M22x1 | 1.50/38 | .16/4 | 4.6/45.1 | 5.1/50 | 3.6/35.3 | 35 | 58/2.05 |

| MS16N | .63/16 | 340 | M24x1 | 1.50/38 | .16/4 | 6.6/64.7 | 7.1/69.6 | 3.6/35.3 | 25 | 64/2.26 |

| MS18N | .71/18 | 400 | M28x1 | 1.65/42 | .16/4 | 7.6/74.5 | 10.2/100 | 5.6/54.92 | 20 | 107/3.77 |

| MS20N | .79/20 | 460 | M30x1 | 1.65/42 | .16/5 | 8.1/79.4 | 12.2/119.6 | 6.6/64.72 | 15 | 116/4.09 |

| MS25N | .98/25 | 620 | M42x1 | 2.44/62 | .20/5 | 8.1/79.4 | 12.2/119.6 | 15.3/150 | 10 | 402/14.18 |

| MS30N | 1.18/30 | 1000 | M48x1.5 | 2.44/62 | .20/5 | 10.2/100 | 12.2/119.6 | 20.4/200 | 9 | 496/17.50 |

| MS35N | 1.38/35 | 1400 | M50x1.5 | 2.44/62 | .20/5 | 12.2/119.6 | 15.3/150 | 22.5/221 | 8 | 436/15.38 |

| MS40N | 1.57/40 | 1800 | M55x1.5 | 2.44/62 | .24/6 | 12.2/119.6 | 15.3/150 | 28.1/276 | 7 | 482/17 |