Butt Contacts & High-Current Probes

A butt contact is an energizing connector that functions as a high current probe by directly pressing it to a contact surface.

The butt contact can flexibly track the uneven surface of a contact point and enables a long-lasting and stable electrical connection. In shipping inspection, using a butt contact helps to simplify work (time reduction) and facilitates design automation. Globetech can inspect and propose a press type butt contact (press type) based on the electrodes’ shapes on the equipment side.

Traditional solutions include using a screw or a standard contact probe to manually tighten a cable to a terminal block. In contrast, butt contacts provide a superior solution because they absorb the friction when they come in contact with an uneven surface. Thus, a long-lasting and stable electrical connection is ensured.

Features

- Design can be customized to fit your requirements

- Can handle current up to 2,000 A

- Passed 1 million life cycle tests (an example of our strict in-house quality control)

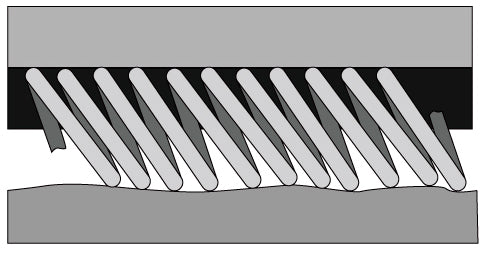

- Coil spring contact flexibly tracks uneven contact surfaces

- Stable energization by having multi-point contacts

- Will not easily scratch the connection destination (unlike spring probes)

- Materials can be changed to suit high temperature and vacuum environment applications

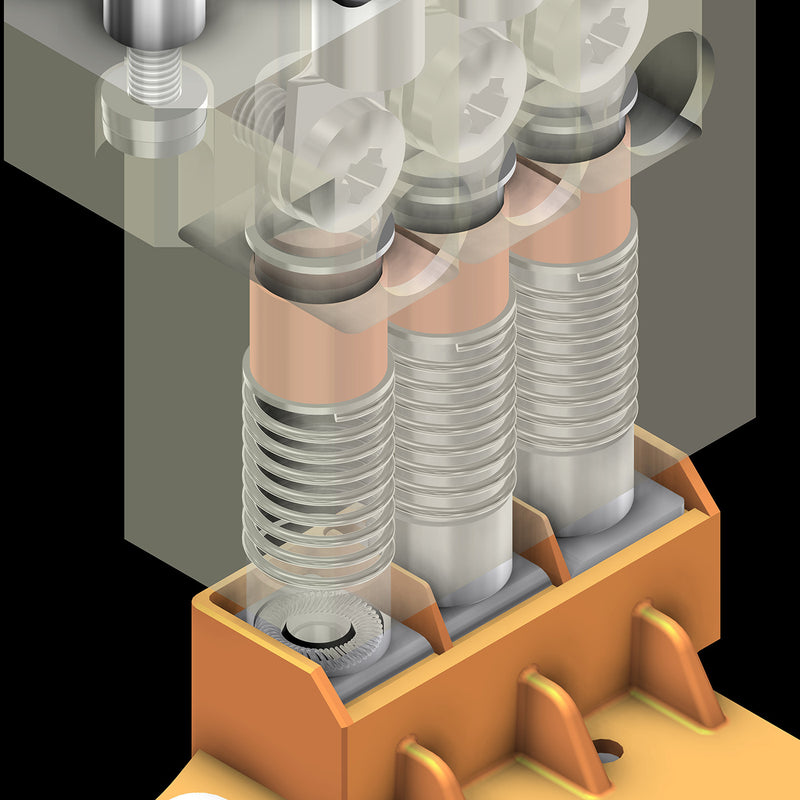

- Supports four-terminal sensing by adding a voltage terminal

Quality Control

Application

- Electric inspection of automotive inverters, ECUs, motors, and batteries

- Electrical inspection of power semiconductors

- Grounding of RF power supply for semiconductor manufacturing equipment

- Electric inspection of smart meters

Custom solutions

Your requirements are unique. The shape, dimensions, and durability of your electrodes will necessitate a custom butt contact. This is our specialty.

Butt Contact Case Studies

One of our customers needed to thoroughly test the operation of all parts of an electric vehicle, including its inverter, IGBT, motor, and battery. During this process, they encountered the following problems, which we solved with a custom butt contact.

Case Study 1

ProblemIf the in-vehicle connector was used for inspection as it was, it had a short life, and after several hundred uses would break and need to be replaced.

SolutionThe durability of Globetech butt contacts reduces the frequency of replacement, resulting in less frequent production line stoppages.

Case Study 2

ProblemThe conventional contact probe did not bend at the tip, so it couldn’t contact multiple points. As a result, the current concentrated on a small number of points, resulting in burning the target.

SolutionOur custom butt contact provided a stable connection and prevents the burning of the object being inspected, thereby eliminating product loss.

Case Study 3

ProblemConventional contact probes scratch the object to be inspected because a sharp tip is embedded in its surface. This resulted in the product being damaged at the time of shipment. The automotive manufacturer then returned it as a defective product.

SolutionGlobetech created a custom butt contact with a soft spring tip, making it difficult to scratch or damage the inspected object.

Case Study 4

ProblemOur customer was unable to automate the inspection of devices because they had to connect the screw to the inspection object manually.

SolutionUsing a custom butt contact by Globetech, they succeeded in automating their inspection process.

Examples

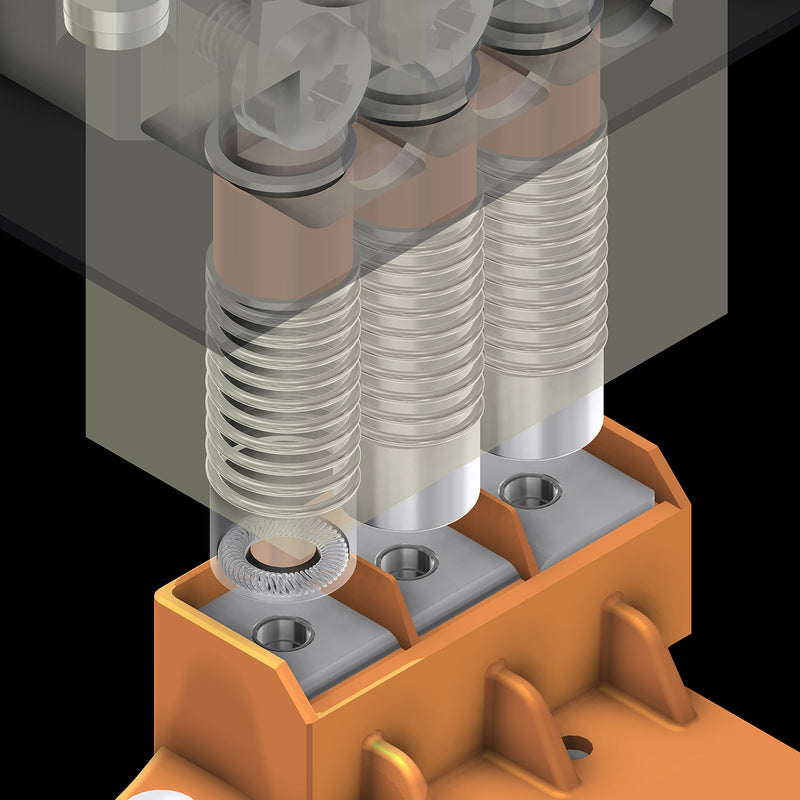

Butt Contact with Spring

The spring absorbs a large stroke deviation, and the coil spring contact at the tip stabilizes the connection.

It is possible to custom a butt contact for a four-terminal inspection in which a spring probe for voltage measurement is embedded in the center of the coil spring contact.

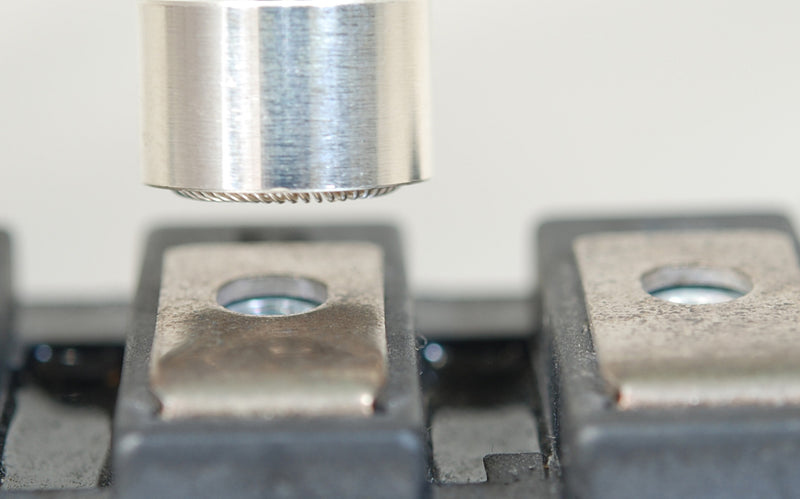

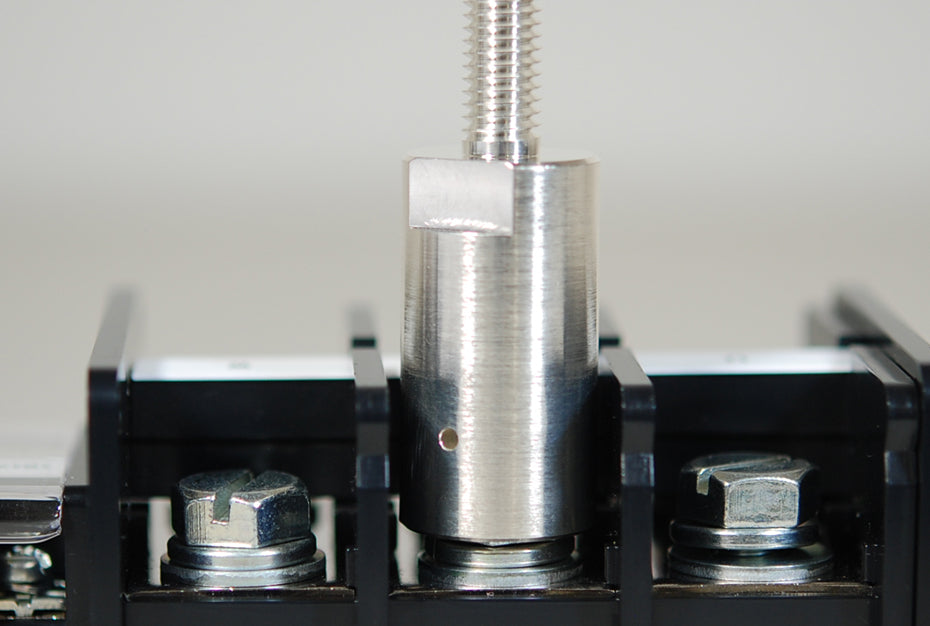

Connecting Terminal Block Screw Heads

This custom butt contact was used in an elective test on a general-purpose terminal block. A more stable energization was established when using two coil spring contacts for the screw head as it enabled energizing two directions, the upper and the side part of the connection. We can custom design and manufacture a butt contact according to the size of the screw head of the terminal block.

Connecting Busbars

The butt contact was inserted between busbars, which stabilized the current flow by reducing the amount of deflection in electrical contacts caused by looseness of screws, warpage of planes, and gaps caused by heat cycles.

Short Distance Connection

Typically, using a plug and a socket increases the axial dimension. However, by pressing the coil spring contact to energize it, we were able to suppress the axial stroke amount. Typically, using a plug and a socket increases the axial dimension. However, by pressing the coil spring contact to energize it, we were able to suppress the axial stroke amount.

Rotating Part Connection

The butt contact can be inserted into a multi-point probe that is rotating at a low speed. It can also be used as an electrical contact that connects a rotating blade such as a knife switch.