Custom Connectors for Automotive PCU & ECU Inspections

Our Solution

Electric and hybrid vehicles have grown in popularity in recent years. Connectors are required for PCU/ECU inspections during the manufacturing process. However, different models require different connector configurations. Furthermore, as technology advances, the specifications and required standards are also evolving.

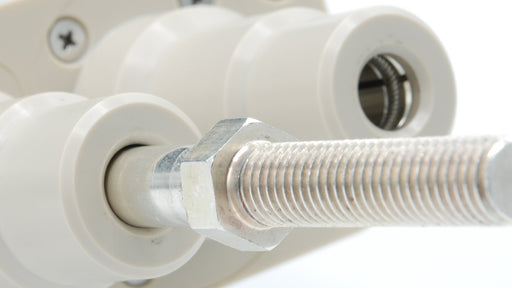

We can provide you with custom connectors designed to fit a particular electrode shape perfectly and meet your durability requirements. Our order-made connectors are made to withstand hundreds of thousands of inspections. Based on your needs, we will propose shapes and materials according to ensure optimum reliability and flexibility.

Features

- Using electrical contacts to stabilize large currents.

- Flexible electrical contacts which enable frequent usage and a longer product lifespan.

- The deflection of the spring absorbs the variation of the inspection object.

- Minimizes damage on the inspected target to almost none at all.

- Custom-design according to the shape and dimensions of the inspection target.

Products

- Power components, power control modules, current transformers

- Drive motors, EPS, compressors

- Batteries, battery management systems

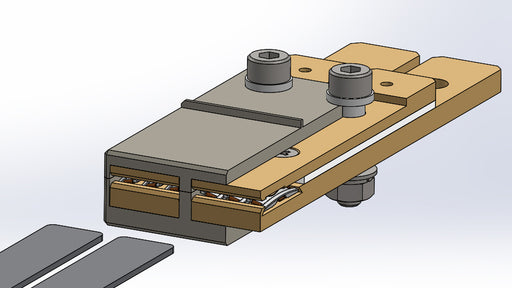

Fork Sockets

Our fork sockets function as a connector between both sides of a plate-shaped electrode, such as a busbar. We design them according to the plate’s width and thickness, including tolerances, and the current-carrying specifications during an inspection.

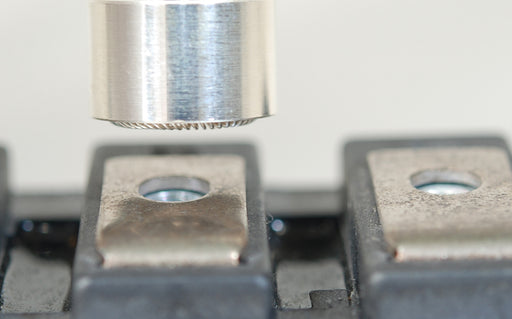

View MoreButt Contacts

A butt contact is like a large current probe that energizes by pressing a connector onto an electrical current-carrying surface of a terminal block. Our butt contacts are designed to provide stable multi-point contact even under conditions such as spring failure. Coil spring contacts with low spring pressure minimize the damage to the product. Each 100A connector is made to endure being used over 1 million times.

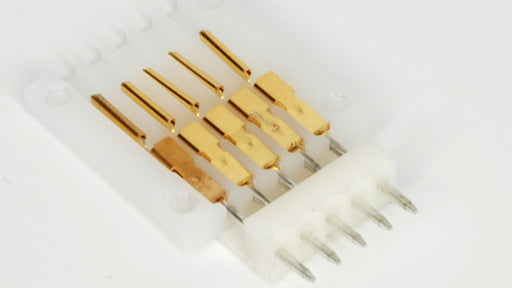

View MoreSockets (0.64mm)

Four-Terminal Sensing Connectors

Contact band and coil spring contacts are used for high currents, while the electrical connections and spring probes are used for voltage measurements. This product is compatible with round sockets, butt contacts, and fork sockets, etc.

View More