Heat-Resistant Connectors

Globetech combines the latest technology and high-quality materials to develop connectors that can withstand up to 680 °C (1,256 ℉).

A standard connector's heat resistance is about 60 (185) to 125 °C (257 ℉). Using a standard connector above its specified temperature limit may cause problems with continuity and insulation that results in melting or burning. Globetech's heat resistant connectors are made to solve such problems.

Our connectors have been widely used in semiconductor manufacturing equipment and other demanding scenarios. Heat resistant connectors are designed according to factors that cause the temperatures to increase, including the environment and factors present during energization.

We can make bespoke designs to meet your environmental criteria. Possible customizations include essential parts such as electrical contacts, conductors, insulators, and external casing. It is also possible to customize the connector for a vacuum environment or high current application.

We want to avoid overspending. Heat-resistant materials are costly. Thus, while it is crucial to choose materials that exceed your maximum expected operating temperatures, overly high specs might result in unnecessary costs. Therefore, please contact us with your requirements, and we will work with you to ensure that you don't overpay.

Features

- Maximum temperature of 680 ℃ (1,256 ℉).

- We can customize the connector's materials based on your use environment.

- Features heat-resistant spring material such as Inconel or stainless steel for electrical contacts.

- Fully customizable based on the number of poles, current value, and shape.

- High current and vacuum environment functions can be added.

Applications

- Heater power supply for semiconductor manufacturing equipment.

- Ion beam filament power supplies.

- Temperature sensor signals of heat treatment furnaces.

- Steel mill heater power supplies.

- Semiconductor burn-in equipment.

Custom Solutions

All high-temperature heat resistant connectors are custom-designed according to our customers' environmental temperature, electrical specifications, and usage requirements.

Case Studies

The following are examples of how our custom high-temperature heat resistant connectors solved our customers' problems.

Case Study 1

ProblemThe manufacturer of metal heat treatment equipment developed a market-leading product. To improve the maintainability, they wanted to change the heater's attachment in the heat treatment equipment from manual screwing to a connector. However, no connectors that could withstand temperatures up to 300 °C (572 ℉) were available.

SolutionAfter installing Globetech's heat resistant connector, the manufacturing heat treatment equipment became smoother with high maintainability. The connector also incorporates a heat-resistant spring material that is easier to use other manufacturers' products.

Case Study 2

ProblemA steel mill worker had to screw their heater power to a terminal block manually. The long working time in a high-temperature environment was dangerous and exhausting.

SolutionGlobetech's heat resistant connector allows them to swap out and replace heaters quickly and easily. The workers can focus on more critical tasks, and they aren't exposed to the hot environment for as long.

Case Study 3

ProblemWhen using a commercially available connector in the heater of semiconductor manufacturing equipment, the connector could not withstand the heat, resulting in poor contact.

SolutionGlobetech developed a heat resistant connector with the same dimensions as a standard commercially available connector. As a result, contact failure was resolved without changing the parts around the semiconductor manufacturing apparatus.

Main Materials

Electrical Contacts

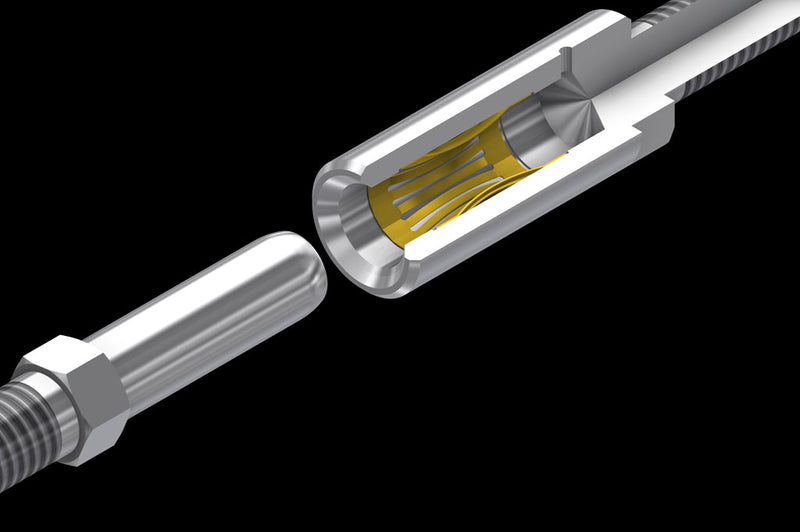

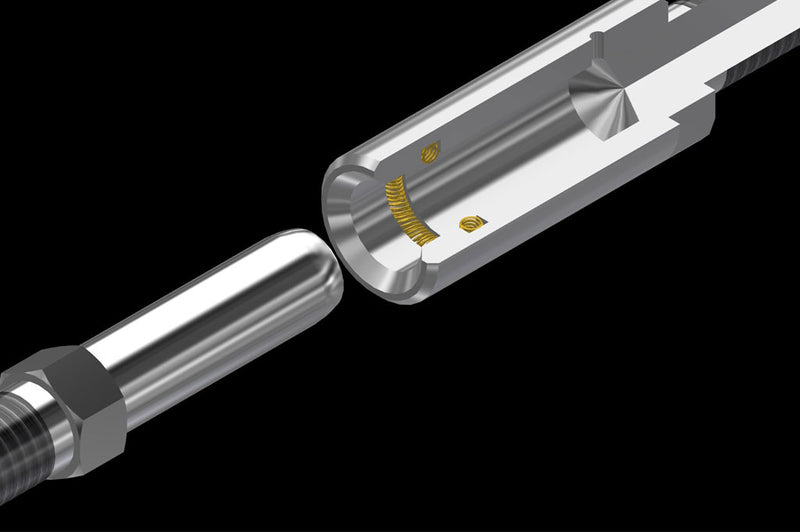

The electrical contacts used in the heat resistant connector must be of high quality. Select a material that can stably conduct electricity without losing the spring property even when exposed to high temperatures.

The electrical contacts used by Globetech for heat resistant connectors are:

- Contact bands

- Coil spring contacts

There are two types of products. Both of which have a lineup of products made with high technological strength using heat-resistant spring materials.

Materials that can be used for electrical contacts:

- Beryllium copper alloy

- Nickel alloy

- stainless

- Hastelloy

- Inconel

Materials used for conductors:

- Copper alloy

- Stainless

- Nickel

- Inconel

Materials used for insulation:

- PTFE

- PEEK

- Polyimide

- Ceramic

Materials used for the case:

- Aluminum

- Stainless

- Inconel

Production Sample

All Globetech heat resistant connectors are custom-designed according to the customer's application. Hence, there is no standard product lineup. Please consult with us regarding the design and your budget.

Heat Resistant Connectors (Without Insulation)

These are samples of the conductor part. The customer will need to insulate the product when installing it on their device.

φ4 Socket Contact/Pin Contact

Current Capacity: 17 AHeatproof temperature: 400 ℃ (753 ℉)

Conductor Materials: Nickel alloy

φ6 Socket Contact/Pin Contact

Current Capacity: 10 AHeatproof temperature: 300 ℃ (572 ℉)

Conductor Materials: Stainless steel

φ1.6 Socket Contact/Pin Contact

Current Capacity: SignalHeatproof temperature: 250℃ (482℉)

Conductor Materials: Copper Alloy

φ5 Latch Lock Contact

Current Capacity: 70 AHeatproof temperature: 180 ℃ (356 ℉)

Conductor Materials: Copper Alloy

Fork Socket for plate thickness .039" (1 mm)

Current Capacity: 1.5 AHeatproof temperature: 300 ℃ (572 ℉)

Conductor Materials: Stainless steel

Heat Resistant Connectors (With Insulator)

Heat resistant connector with customized insulation, case, and locking mechanism. Insulators and case materials are selected according to the operating environment temperature.

2P In-line Connector

Current Capacity: 10 AHeatproof temperature: 220 ℃ (428 ℉)

Insulator: PTFE

Lock pipe: PEEK

1P panel mounting connector

Current Capacity: 200 AHeatproof temperature: 200 ℃ (428 ℉)

Insulator: PEEK

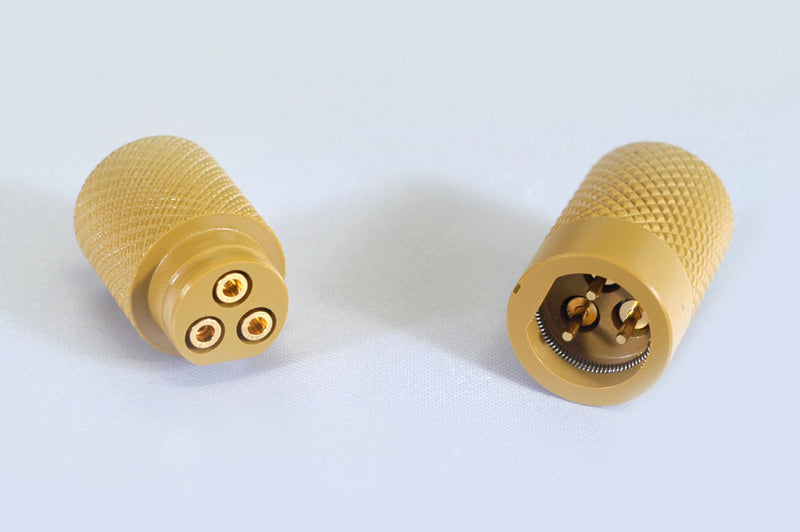

3P In-line Connector

Current Capacity: SignalHeatproof temperature: 300 °C (532 ℉)

Insulator: Polyimide

1P Connector with Lock Lever

Current Capacity: 200 AHeatproof temperature: 200 ℃ (428 ℉)

Insulator: PTFE

Case: Stainless steel

6P In-line Connector

Current Capacity: 5 AHeatproof temperature: 200 ℃ (428 ℉)

Insulator: PTFE

Case: Stainless steel