Contact Bands

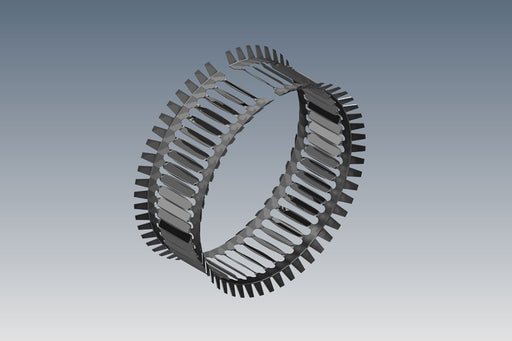

A contact band is an electrical contact that is used between a socket contact and a pin contact to carry electricity stably.

Globetech's contact band uses a beryllium-copper alloy. Using a contact band for the connector, we realize a mechanically and electrically highly reliable connector due to its excellent spring properties and power flow.

By changing the type of contact band, we can realize durable connectors with low contact resistance, ample clearance between the plug and socket diameter, and requiring less force to insert/remove.

Also, by changing the material, it is possible to design a corrosion-resistant contact that can be used in a high-temperature environment.

Typically, Globetech does not sell contact bands alone. We are proposing a contact band built into the connector. However, some customers require large quantities of contact bands. In any case, please contact us with your requirements and we can find a suitable solution.

Features

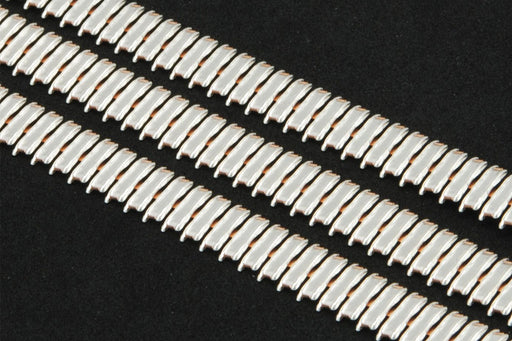

- Louver structure suitable for energizing large currents.

- Stable energization by multi-point contact.

- Low contact resistance suppresses heat generation even with high current.

- Superior capability to remove oxide film thanks to the wiping function of the heat cycle.

- We can manufacture heat resistant and corrosion resistant contact bands by changing the material.

- Not only socket mounting but also plug mounting is possible.

- The contact band can be sold separately for high volume applications.

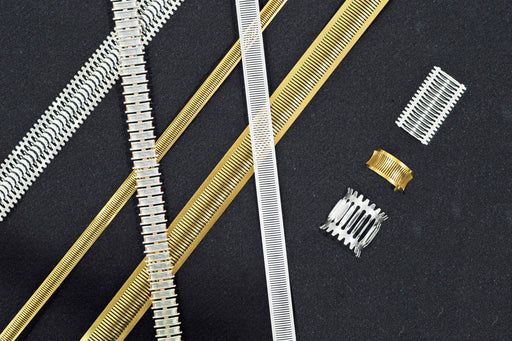

Media

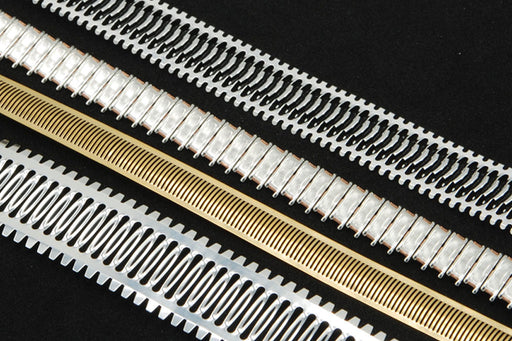

Contact Band Series

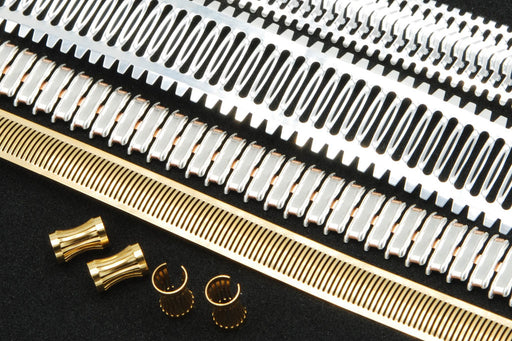

| Series | Contact Shape | Wearing Width | Louver Pitch | Current Value/Louver |

|---|---|---|---|---|

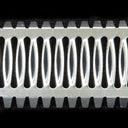

| GCB1a |  |

.70" (18 mm) | .10" (2.54 mm) | 25 A |

| GCB1b |  |

.70" /(18 mm) | .10" (2.54 mm) | 25 A |

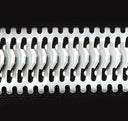

| GCB3 |  |

.49" (12.5 mm) | .039" (1 mm) | 7 A |

| GCB4 |  |

.33" (8.5 mm) | .031" (0.8 mm) | 5 A |

| GCB5 |  |

.22" (5.5 mm) | .027" (0.7 mm) | 3 A |

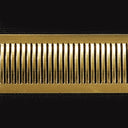

| GCB8 |  |

.39" (10 mm) | .13" (3.3 mm) | 45 A |

| GCB12 |  |

.52" (13.1 mm) | .08" (2 mm) | 25 A |

Applications

- Internal connection of circuit breakers, switches and disconnectors of electric power and substation equipment.

- Connection between bus bars carrying high current.

- Grounding of RF power supply for semiconductor manufacturing equipment.

Custom solutions

Custom Contact Band Case Studies

Real-life examples of how our custom contact bands solved major issues for our customers.

Case Study 1

ProblemExpensive contact bands pushed up the final product cost.

SolutionSwitching to Globetech contact bands dramatically reduced costs.

Case Study 2

ProblemProcuring contact bands was taking three months or more.

SolutionSwitching to Globetech contact bands removed this delay and allowed the manufacturer to stabilize its production schedule.

Case Study 3

ProblemWhen using finger contacts and spiral shields in the high-frequency (RF) grounding part of semiconductor manufacturing equipment, contact failure occurred, resulting in burning.

SolutionSwitching to Globetech's high current contact bands eliminated the burning.

Case Study 4

ProblemThe Finger Contacts and Spiral Shields had weak spring properties, so they deteriorated once used and need to be replaced each time.

SolutionSwitching to Glovetech contact bands dramatically reduced the replacement frequency due to their excellent spring properties.

Examples

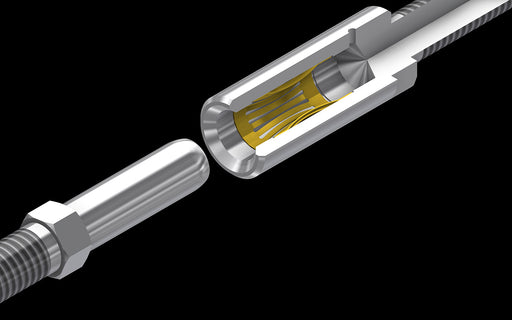

Connectors for Electromagnetic Stirrers

- Current Value: 1,000 A

- Nominal Diameter: φ30 mm

- Contact Band: GCB1b

- Feature: The socket is silver brazed to the angle bus bar.

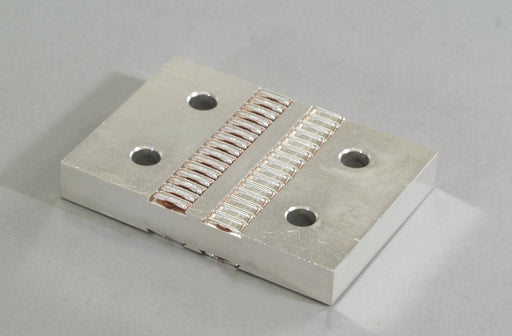

Flat Contact

- Current Value: 1,000 A

- Contact Band: GCB8

- Usage: Sandwiching between busbars.

- Benefit: Stabilizes the current flow due to the amount of deflection of the electrical contacts for looseness of screws, warpage of planes, and gaps caused by heat cycles.