Custom Connectors for Semiconductor & FPD Manufacturing Equipment

Our Solution

In the process of forming circuits on silicon and glass substrates in semiconductor manufacturing equipment and flat panel display (FPD) manufacturing equipment such as liquid crystal and organic electroluminescence (OLED), connectors for heater power supplies, thermocouples, and plasma power supplies are required.

These connectors must withstand harsh environments such as vacuum, high temperatures, high currents, and high frequencies, so commodity connectors cannot be used.

Globetech's custom-made connectors are flexible in terms of shape and the materials they are made of, so they have been used for many years for etching, sputtering, evaporation, CVD, PVD, and ion implantation equipment.

Please contact Globetech for more information about connectors for semiconductor and FPD manufacturing equipment.

Features

- A hermetic connector that connects the inside of a vacuum chamber to the atmosphere using sealing technology.

- A high-temperature, heat-resistant connector for use in a vacuum and a heat resistant connector for use in a high-temperature environment, realized by a custom-ordered connector with a choice of materials.

- High-frequency connectors for high-frequency connections using electrical contact technology suitable for high-current conduction.

Products

- Etching

- Sputtering

- Vacuum deposition

- CVD

- PVD

- Ion Implantation Systems

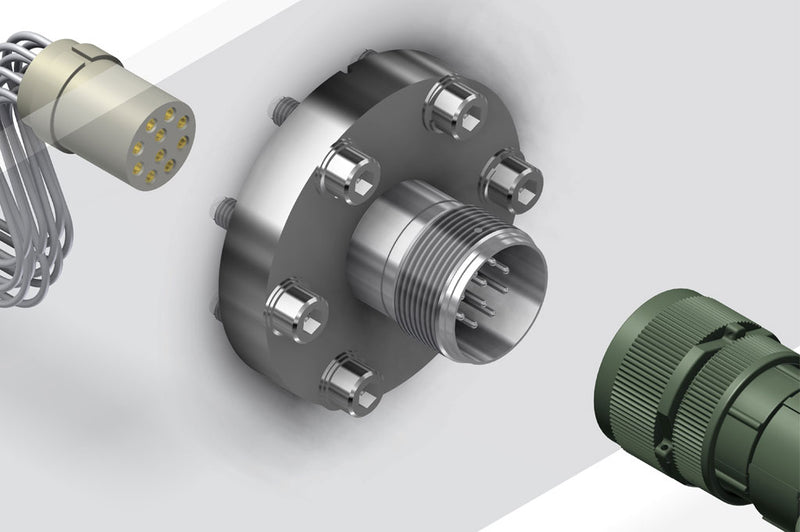

Vacuum Connectors

Hermetic connectors are the best solution in the following cases:

- Introducing a high current power source, such as a heater, from the air while maintaining a vacuum.

- When thermocouple sensors and other vacuum devices' electrical signals are transferred to atmospheric measuring instruments.

For connectors brought into a vacuum to be attached and detached in a vacuum, we offer in-line connectors for vacuums that use only low outgas materials.

Combining hermetic connectors and vacuum in-line connectors can significantly reduce maintenance work.

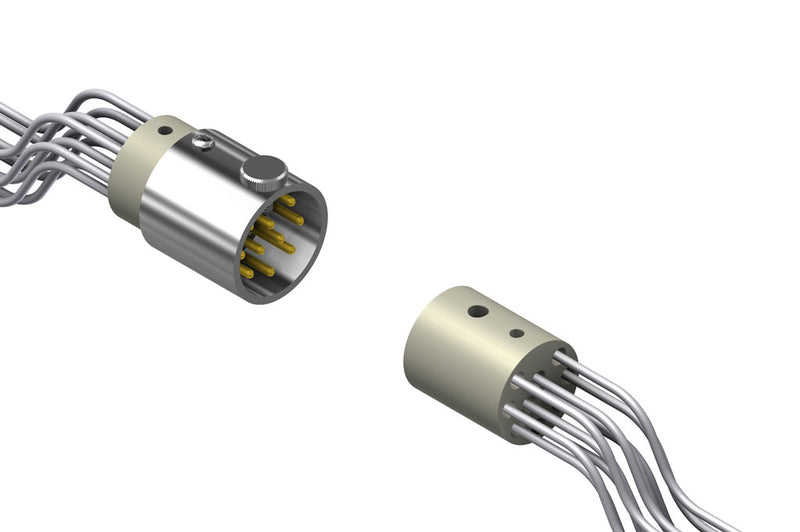

View MoreHigh Current / High-Frequency Power Supply Connectors

Power supplies used in plasma generation (heaters, DC, and high-frequency) are becoming more popular and expected to withstand increasingly higher currents. Thus, it is essential to adopt connectors that can stably conduct electricity in these scenarios.

Globetech's high current/high-frequency power supply connectors are custom made with contact bands and coil spring contacts. This facilitates stable current flow while minimizing the risk of heat generation and poor connection.

When used in a vacuum or high heat environment, the choice of materials allows them to be carried into a vacuum and be heat resistant.

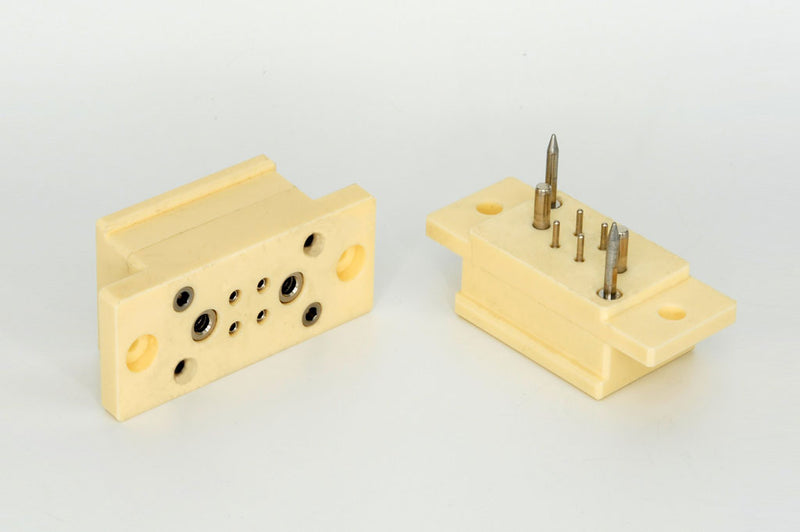

View MoreHigh-Temperature Heat-Resistant Connectors

Silicon wafers and glass substrates are processed in high-temperature environments using heaters, which means that connectors used near the heater are also exposed to high temperatures.

Globetech's high-temperature heat resistant connectors are designed with suitable materials for your application's temperature settings. For the electrical contacts of custom made connectors, we can use copper alloys and heat resistant spring materials such as Inconel, and we can manufacture heat resistant connectors for use in vacuum environments.

View MoreRF Grounding Connections

In devices that generate plasma in a vacuum chamber, the chamber also runs at high frequencies, requiring the use of electrical contacts at the joints of the stainless steel or aluminum vessels. Globetech's contact bands can be used for large diameters of several hundred millimeters in diameter and can be used for large volume ground connections in vacuum vessels. Compared to spiral shields and shielded fingers, these contacts are easier to install, less likely to damage the contact surface, and more suitable for high current flow.

View More